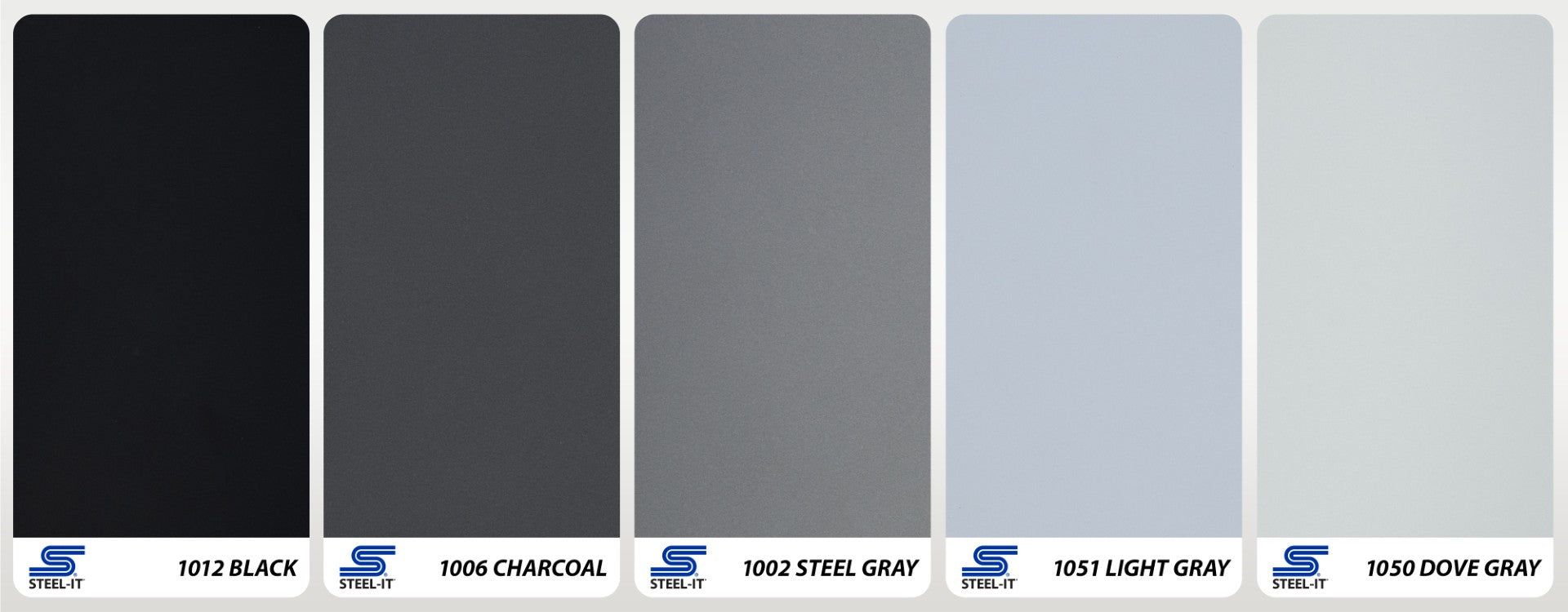

Steel It

Steel-It Black 1012D Polyurethane Aerosol (Single 12oz Can)

Steel-It Black 1012D Polyurethane Aerosol (Single 12oz Can)

MCQUEEN

190 South McQueen Road

Suite 109

Gilbert AZ 85233

United States

Steel-It Black 1012D Polyurethane Aerosol (Single Can)

The formulation you all have been waiting for! STEEL-IT Black has all the same key benefits as our "Signature" gray which is packed full of 316L Stainless Steel, Anti-Corrosive and Weldable!

The STEEL-IT Polyurethane Coating System features a unique stainless steel leafing pigment, and provides optimum weather, abrasion, and corrosion resistance in off-road racing applications. The easy to apply system yields a hard, non-toxic, metallic finish that protects a multitude of metallic and non-metallic surfaces from ultraviolet rays, chemicals, oils, alkalis, food acids, water immersion, abrasion, and high-pressure washdowns.

This single component coating does not require complicated mixing. Apply it directly from the can, it is air dried and requires no baking or heating. USDA-approved for use in the food processing and handling industry where incidental food contact may occur, STEEL-IT Polyurethane #1012 blends polyurethane resin with Type 316L stainless steel leafing pigment to produce a rugged, non-toxic, satiny metallic finish.

key features

- Superior anticorrosion coating

- Single component coating that air dries

- Handy aerosol for easy-to-apply original jobs and touch-up work

- UV-resistant

- Weldable! – No need to grind off the coating when repairs or add-ons are required

- Withstands high-pressure washdowns without chipping or flaking

- Temperature Rating: 200 °F

- The identical, high-quality coating as the Polyurethane Topcoat options available in quarts and gallons

Application Guide:

A 12oz aerosol can of STEEL-IT Polyurethane Aerosol (black and gray) has practical coverage of roughly 15 square feet per aerosol can, when applied at the recommended 16 mils wet film thickness to achieve 3 mils (.003” or 75 microns) dry film thickness (DFT) per coat.

WHY DOES STEEL-IT COST SO MUCH?

- STEEL-IT is a high-performance industrial coating made with high quality, and custom materials

- Both our primers and topcoats contain an abundance of custom-engineered, 316L stainless steel micro flake.

- STEEL-IT is not a common, every day, decorative paint. It’s a sophisticated, complex product that has demonstrated remarkable performance across diverse industries and multiple applications in some of the harshest conditions imaginable.

DO I HAVE TO USE STEEL-IT'S PRIMER? CAN'T I USE A MUCH LESS EXPENSIVE SHOP PRIMER?

- Yes, it may work. However, unlike the case with many primers in the marketplace, STEEL-IT primers are not designed to enhance adhesion to the substrate, but are, in their own right, high performance anticorrosion coatings that contain, in addition to anticorrosive materials, the same 316L stainless steel micro flake used in STEEL-IT topcoats. Thus STEEL-IT primers form a critical part of providing the maximum protection against corrosion, chemicals, abrasion, impact, temperature cycling, and other harsh conditions.

DO I HAVE TO REMOVE EXISTING COATINGS OR RUST BEFORE APPLYING STEEL-IT?

- All the rust must be removed. STEEL-IT is not a rust neutralizer. If rust is trapped under the coating, it will continue to propagate.

- Whether it’s necessary to remove existing coating, the SSPC requirements indicated in our surface preparation instructions in the Application Guides specify how much original coating can remain.

WHAT IF I CAN'T GRIT BLAST? ARE THERE OTHER METHODS I CAN USE TO PROPERLY PREPARE THE SURFACE?

- It depends on the application. For example, if you require the STEEL-IT High Solids Epoxy System, then grit blasting is absolutely necessary.

- • In other cases, some of our customers have found that mechanically sanding the surface using #36 grit paper provides a similar surface to grit blasting.

- What we want you to avoid are methodologies that merely clean the surface without scarifying it and providing an aggressive profile per our instructions. Such methods might be needle scaling, soda blasting, dry ice blasting, glass beading.

CAN I USE STEEL-IT TO COAT OVER GALVANIZED STEEL?

It depends on how long the item has been galvanized. The chemistry of galvanized steel changes over time:

- During the first few days, the surface is zinc metal and merely requires proper surface preparation.

- For the next four to six months, the surface becomes zinc oxide, which is very difficult to paint because it’s a hard, lubricious surface and the zinc oxide on the surface tends to be powdery and therefore difficult to adhere to. As a consequence, the oxide needs to be profiled and then passivated. Passivation can be accomplished using any commercially available vinyl wash primer.

- From then to about a year, the zinc oxide absorbs environmental moisture and slowly converts to zinc hydroxide, which also requires profiling and a vinyl wash primer.

- After a year or so, in addition to the oxygen and water, the surface also begins to absorb carbon dioxide and the surface now becomes zinc carbonate. Zinc carbonate is stable and amenable to coating, and therefore requires just profiling.

HOW LONG DO YOU GUARANTEE THE COATING TO LAST?

- We cannot guarantee the longevity of the coating. The success of a coating job depends critically on proper surface preparation and application. Since we do not provide those services, we cannot take responsibility for how well the coating performs over time.

- We provide the proper instructions to achieve best results. However, even assuming best results, reasonable conditions of use vary widely. We would have to know precise conditions over precise periods of time. What we can say, is that in some applications, STEEL-IT can last up to 10 years, in others 20 years, others even longer, and in others 5 years. Nonetheless, we are confident that if you compare STEEL-IT to another coating under the same conditions, STEEL-IT will hold up longer.

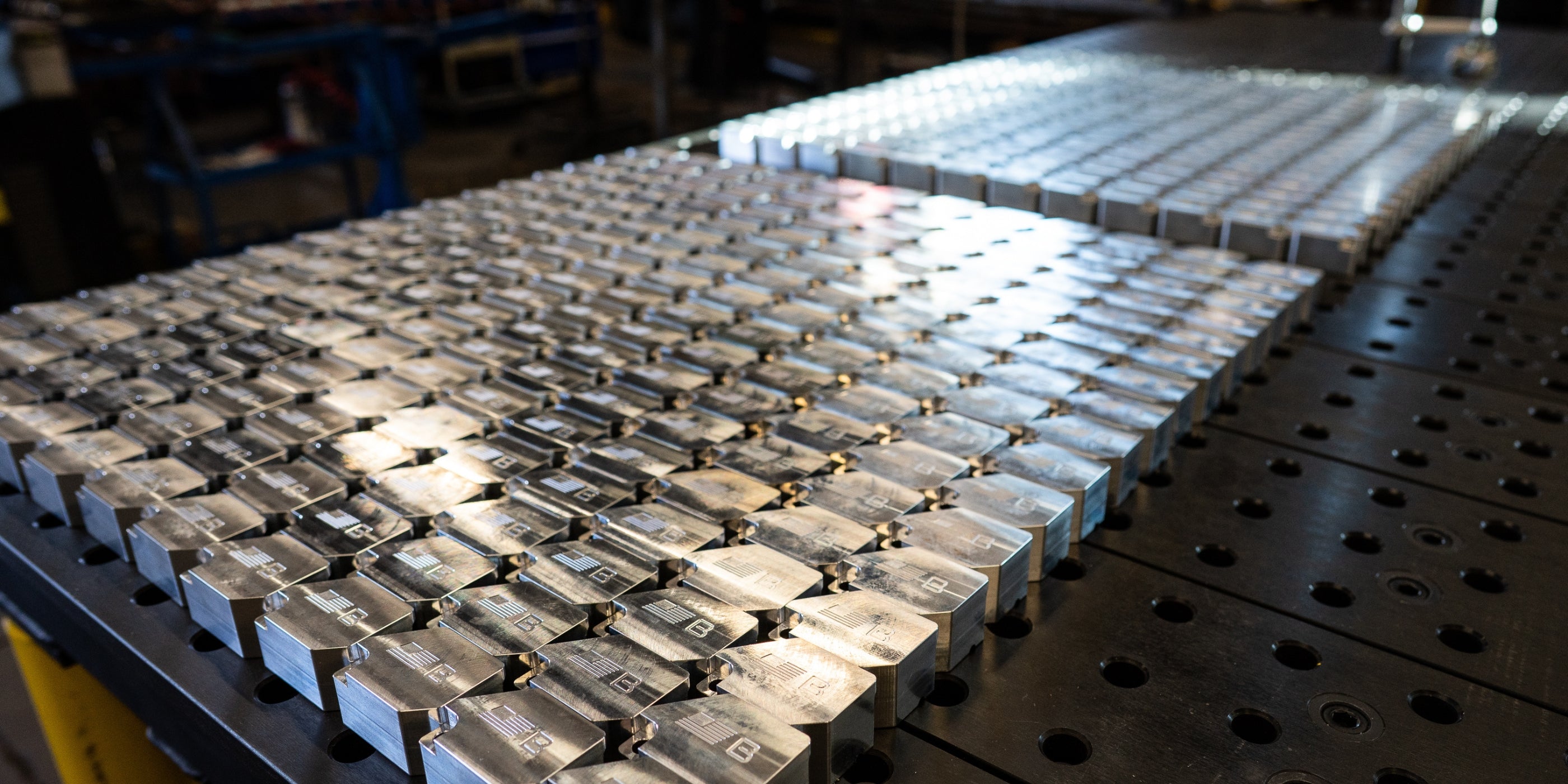

American-made Excellence

SDHQ: Built for Adventure

Experience American-made excellence from SDHQ, your fellow off-road enthusiasts. We take pride in crafting high-quality, custom products right at our headquarters for unparalleled performance and durability.

Check out what 'SDHQ Built' means for us as well as our customers: